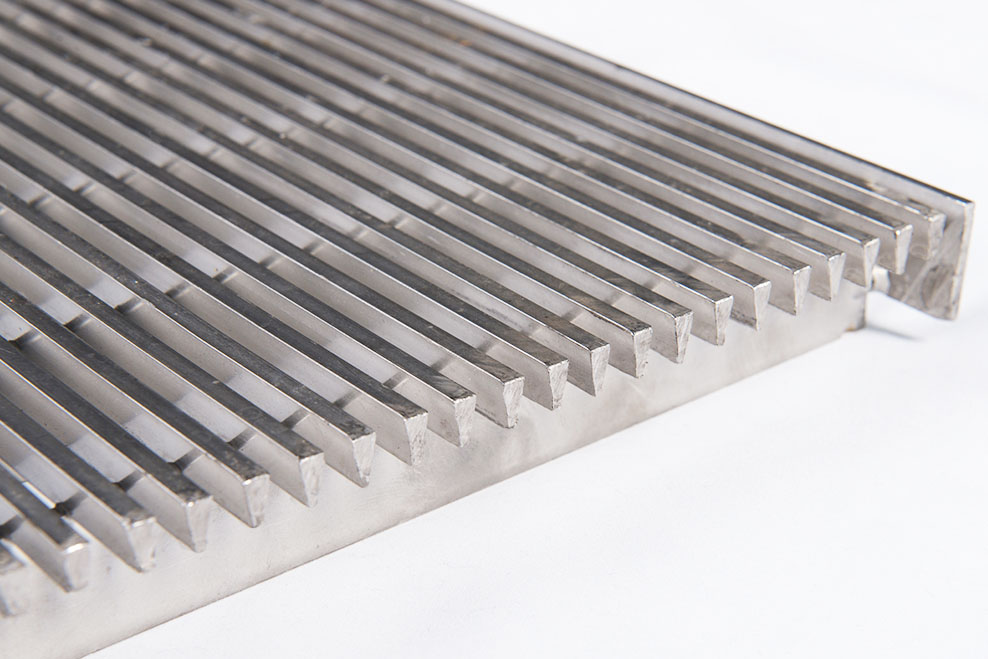

Stainless Steel Wedge Wire Screens

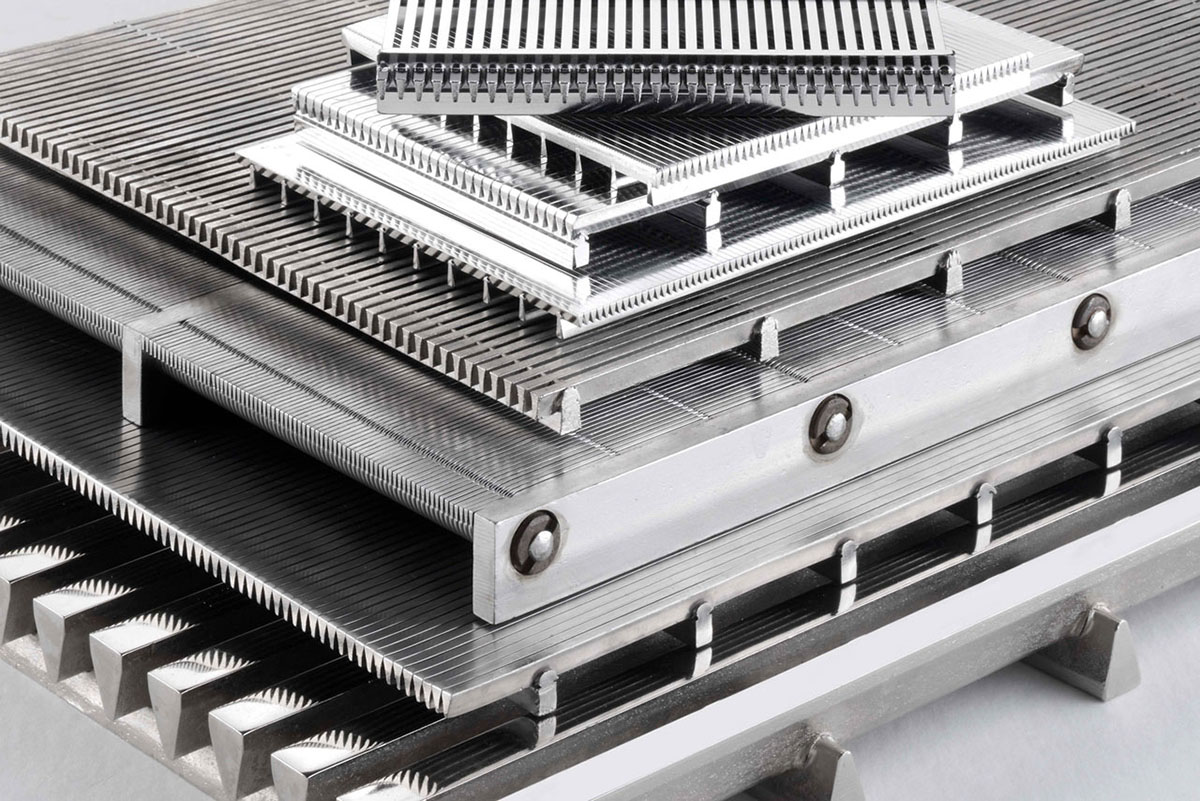

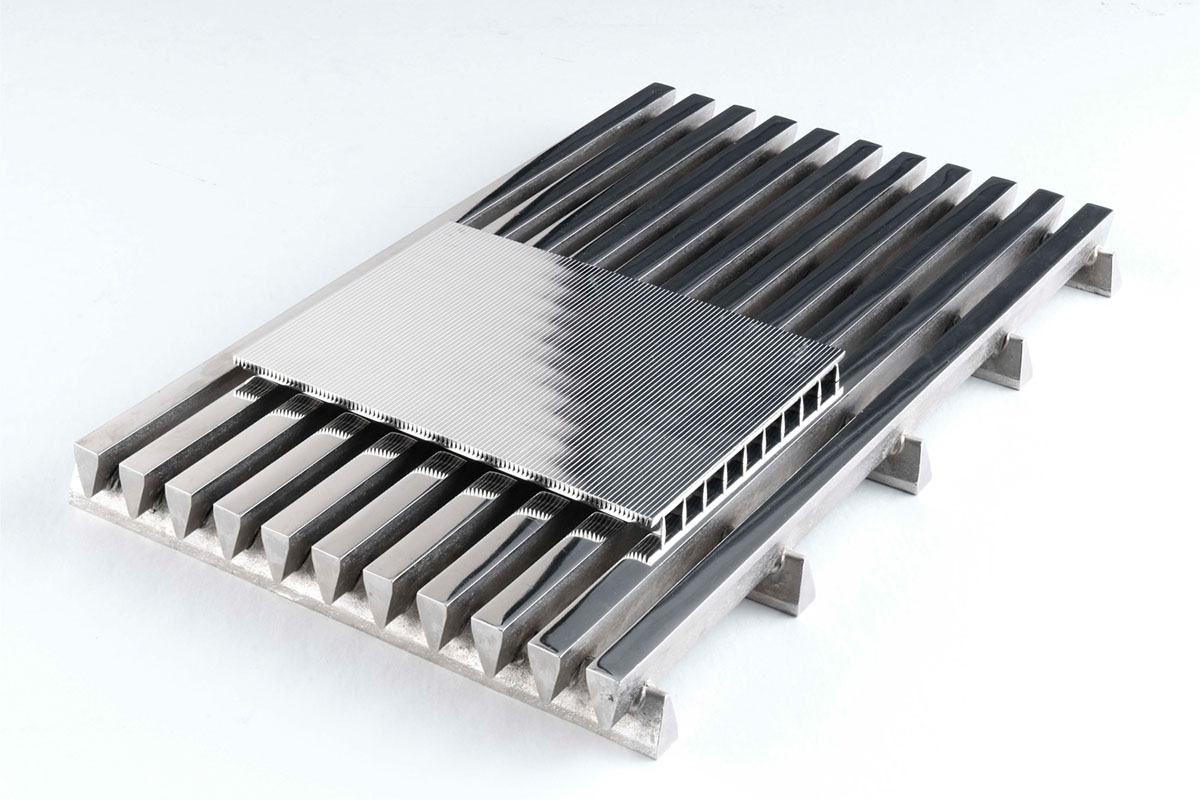

Stainless steel wedge wire screens are made by welding V-shaped wires on the support rods to form a metal filter product with high mechanical strength and non-clogging features. The profile wire is the filter surface, and the support rod plays a supporting role. Stainless steel wedge wire screen provide a continuous slot that expands inward so that the liquid and particles can easily pass through the screen. The continuous slot maximizes the opening area, prevents clogging, and ensures the required particle retain through the precise slot size. It is an ideal solution for screening, filtering, media retain, dewatering, sizing, collection and distribution.

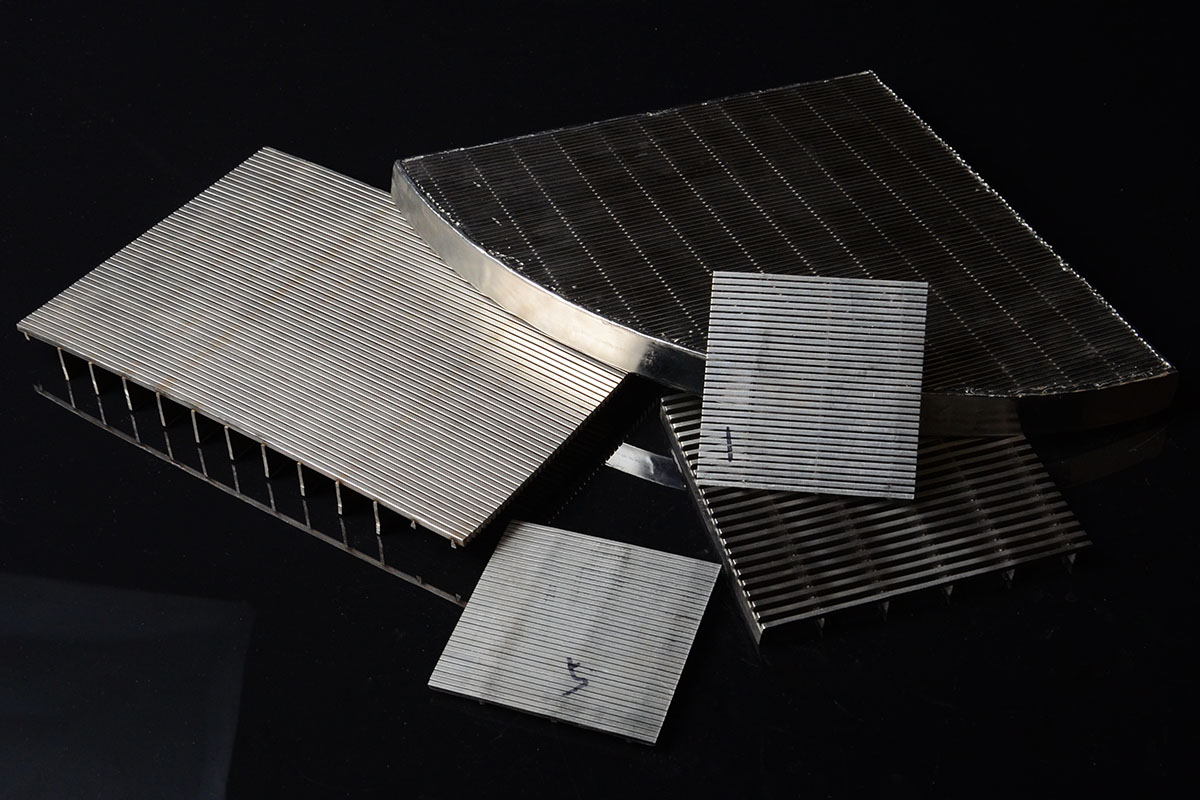

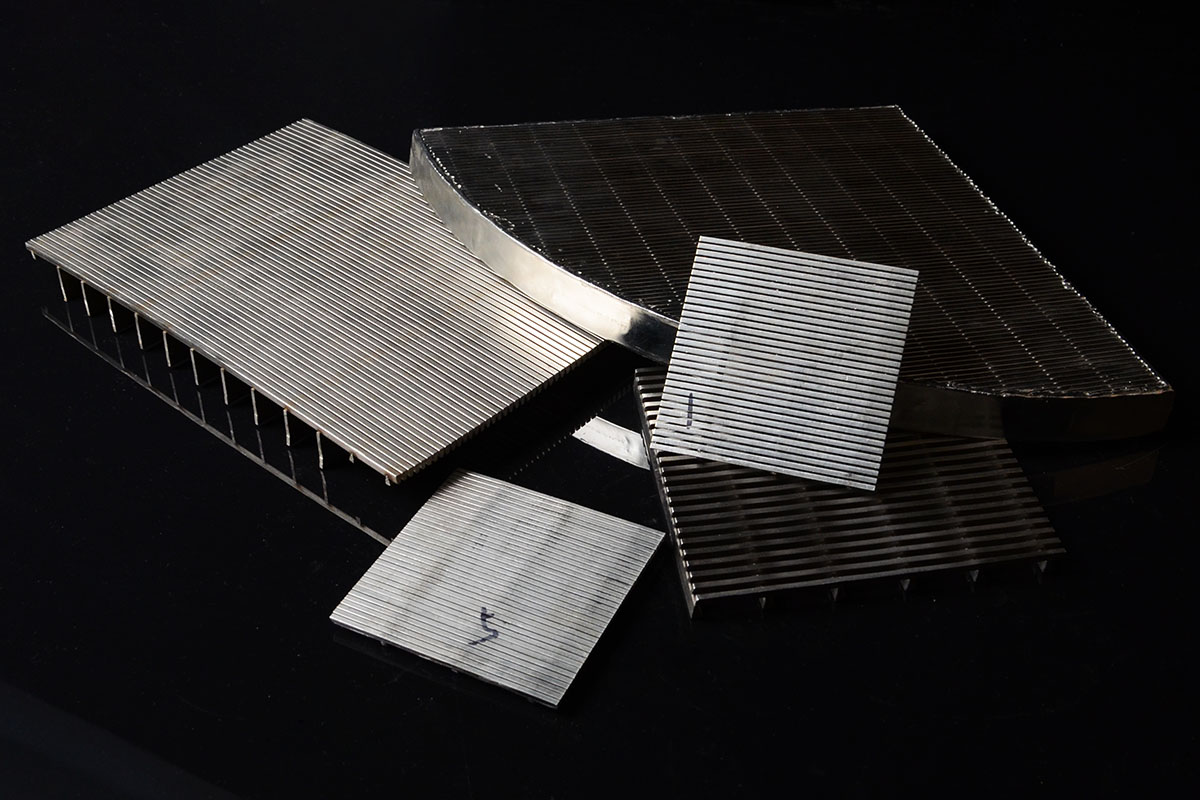

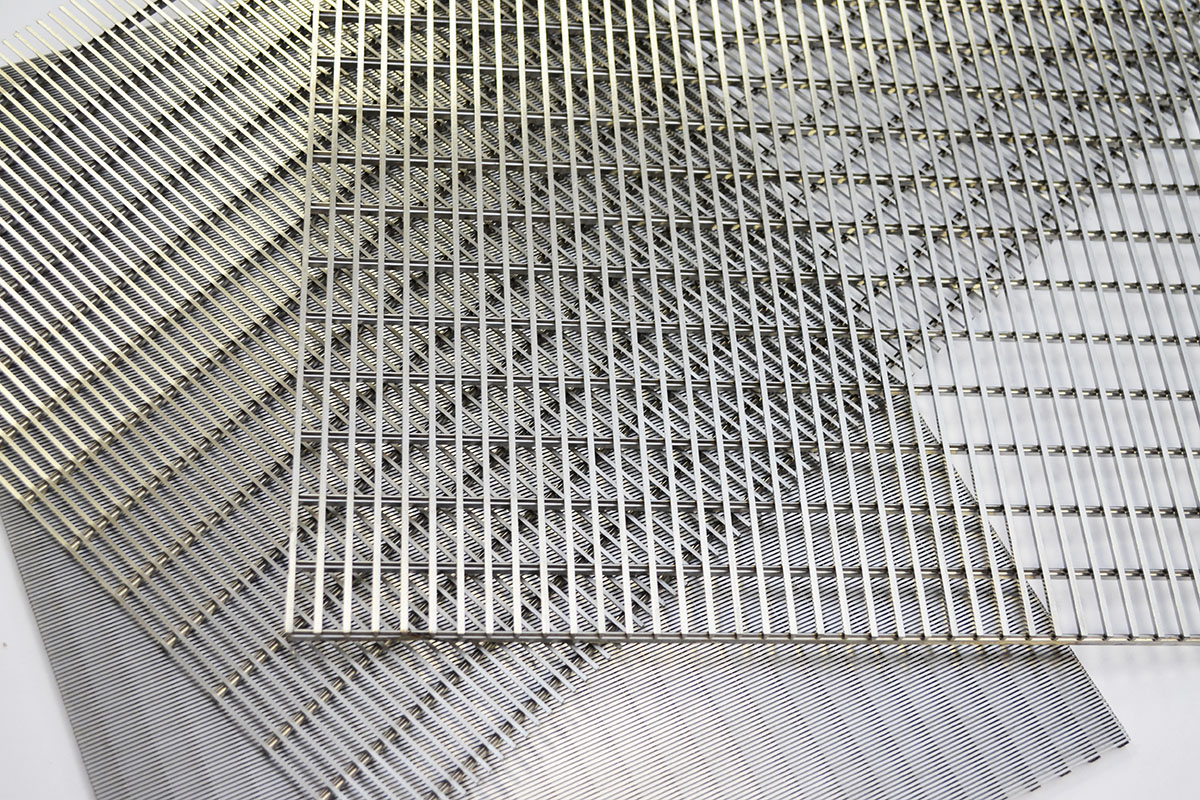

Our stainless steel wedge wire mesh screens have a variety of different structures and shapes, including flat, cylindrical, basket, curved or special shapes. In addition, our stainless steel wedge wire screens are available in various sizes and open areas to meet your project requirements.

Features

- Minimize clogging and easy to clean: Wedge wire screen has a “triangular” structure, which means that when the material passes through, the point of contact with the screen is very small. The slot widens downward so that no blockage is formed.

- Higher strength and durability: The wedge wire screen has higher strength and durability than other filters such as wire mesh or perforated sheet. For other filters, with long-term use, the filter layer will wear out, the pore size will change, and the filtration accuracy will also change greatly. The wedge wire filter does not have this problem and can be used almost indefinitely, thereby reducing operating costs.

- Large opening area, high capacity and high flow: Compared with other types of metal filters, its continuous slot structure has a larger open area.

- Design flexibility and diversity: Wedge wire screens are available in various shapes, such as panels, tubes, conical, basket and curved.