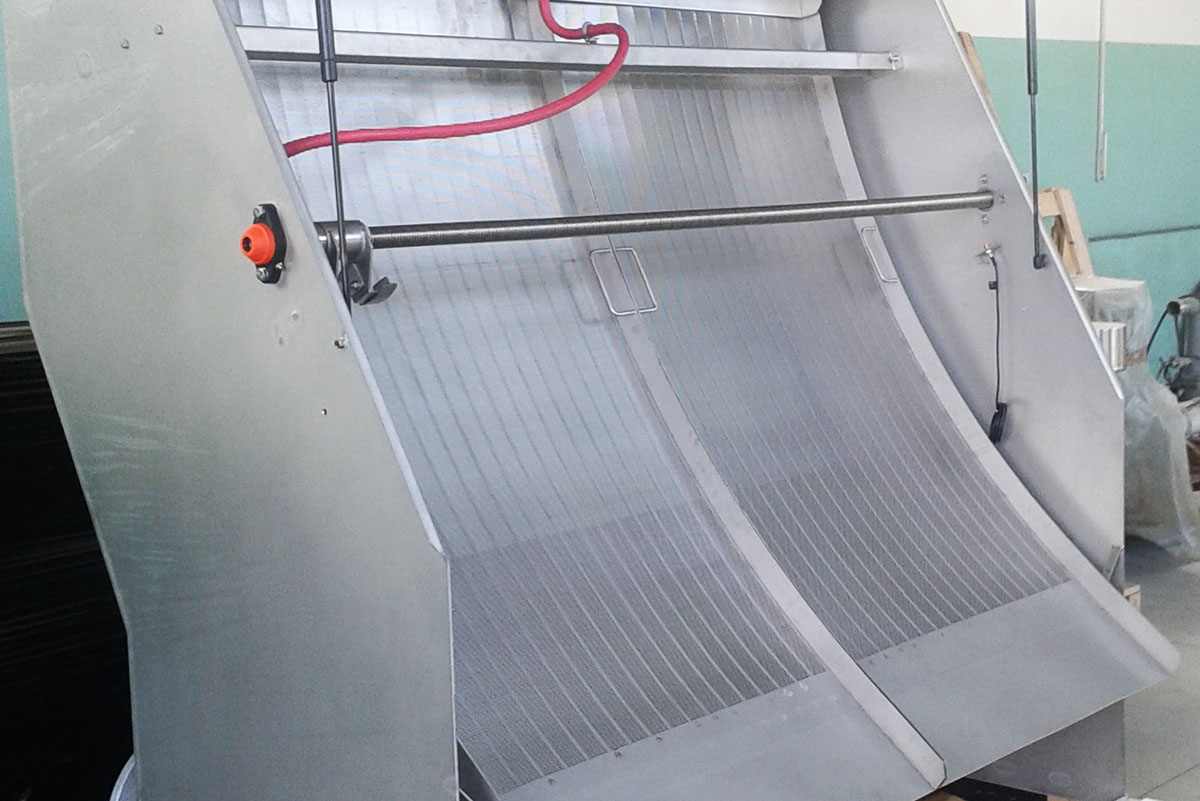

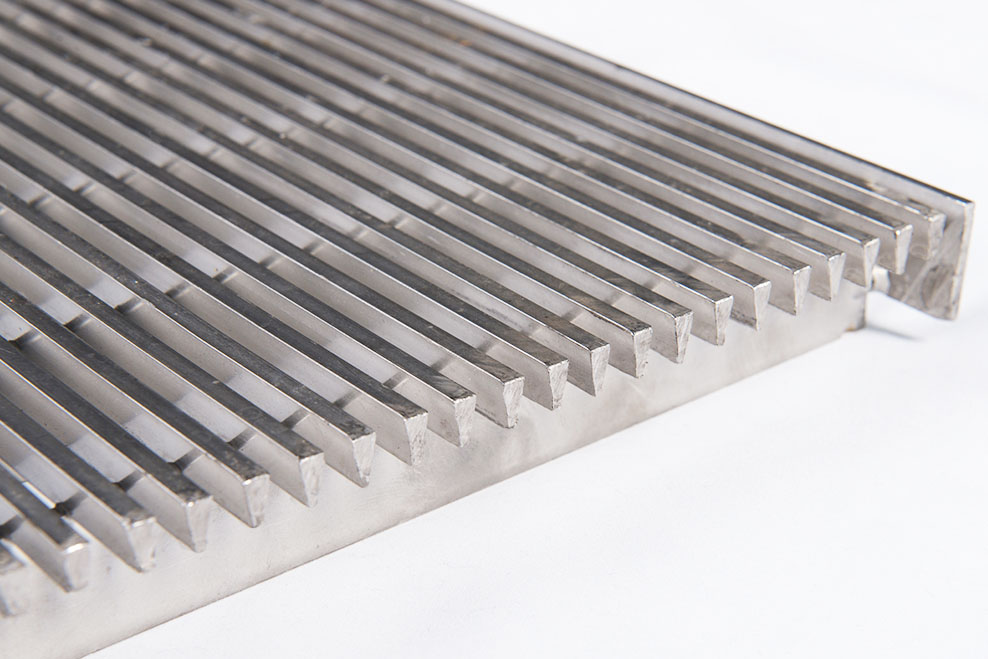

Static Curved Wedge Wire Sieve Bend Screen

Sieve bend screen is a curved wedge wire screen filter, used for particle classification and debris filtering. Because it does not require power drive, it is also called static wedge wire screen.

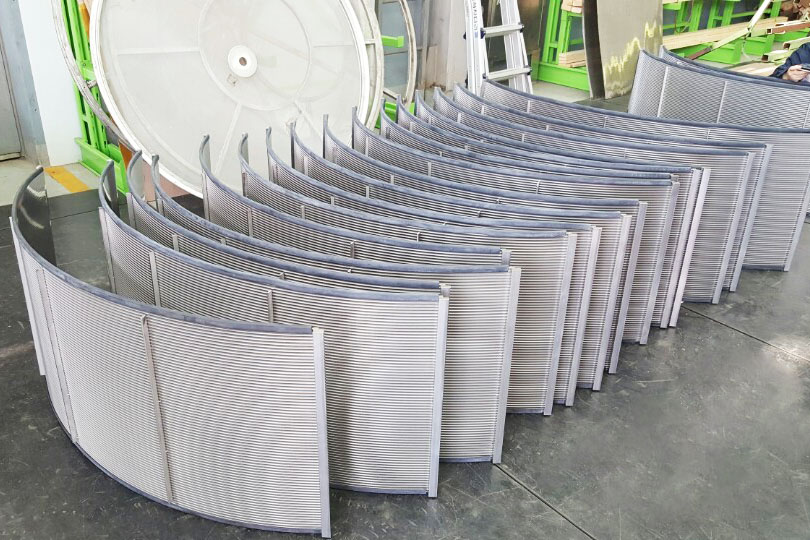

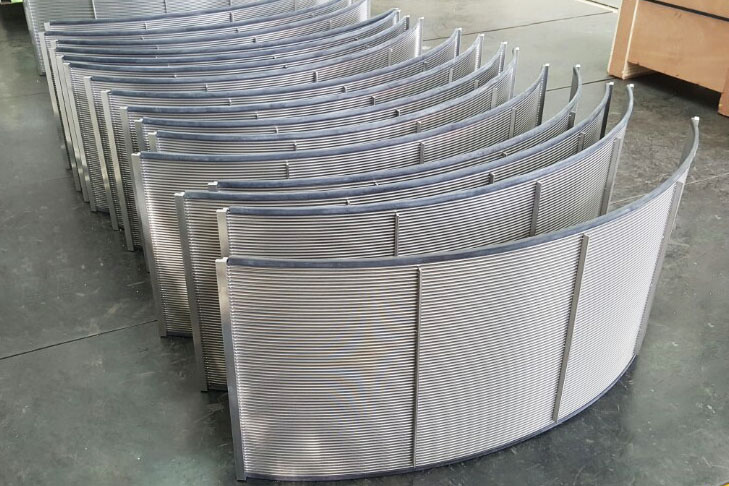

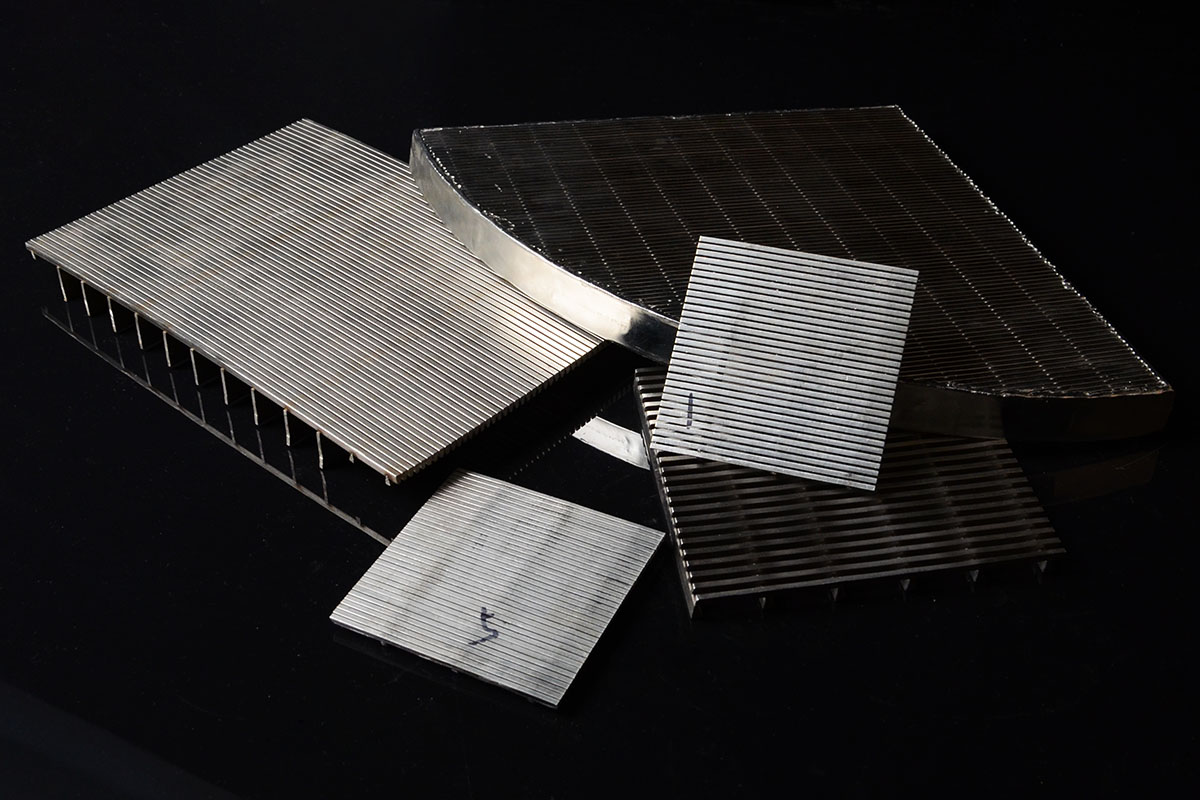

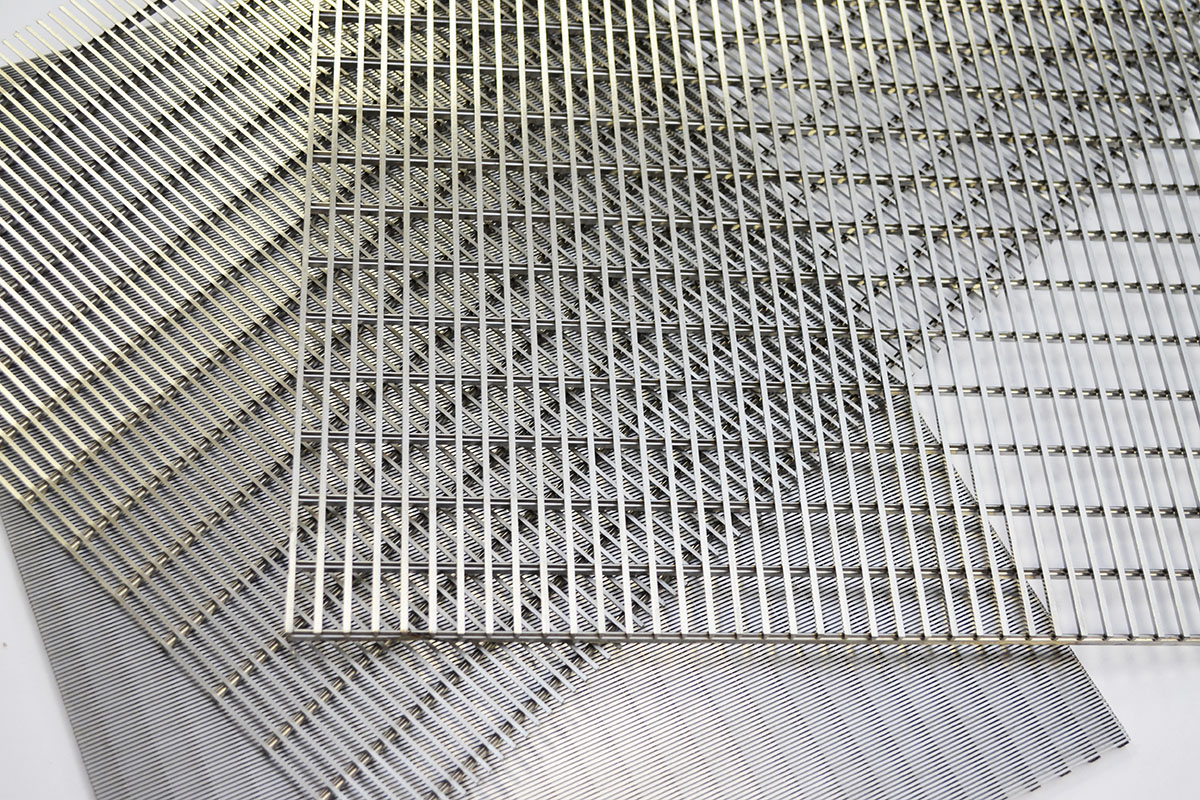

Sieve bend screen is made by welding V-shaped stainless steel profile steel wires to vertical support rods. Then the wedge wire screen is cut and bent into a common arc (45°, 60° or other arcs) to form a curved wedge wire screen. It is suitable for removing solids from liquids or for separation of dry materials, and is ideal for screening and dewatering applications. The sieve bend screen can be made into various curvatures and apertures to adapt to different filter materials.

Working principle

Static wedge wire screen features a continuous slot, which provides high-efficiency filtration performance. Compared with the conventional flat wedge screen, it has a larger capacity. This is because the gravity increases when the material flows to the curved surface, thereby providing higher material throughput and better filtering effect.

Features of Curved Sieve Bend Screen

- No clogging: The continuous slot formed by the V-shaped profile wire can ensure the minimum contact between the particles and the slot, thereby minimizing clogging.

- High filtration accuracy: The precise slot size can meet customer requirements.

- High capacity: The flow rate is larger than the traditional flat wedge screen.

- Easy to clean: The screen can be easily cleaned by scraping or backwashing.

- Durable structure: Each intersection of the profile wire and the support rod is welded to make the structure stronger.

- Low pressure drops

Applications

The sieve bend screen is mainly used for

- Screening, dewatering, sizing and wastewater treatment applications.

- Sewage treatment

- Food, starch, sugar factories

- Mineral processing

- Pulp and paper

- Textile factory